|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Reed Valve & Valve Plates are used in Air Compressors for different types of applications. Valve Plates are made from High Chromium Stainless Steel material. Valve Plates are manufactured and heat treated in precision SPM's Flatness, Parallelism and surface finish of valve Plate is most important factor to increase efficiency of compressor valves. We have all testing facilities to check Flatness, Parallelism and surface finish of valve plates. We have developed a inique manufacturing process from our decades of experience and research. We are offering wide range of Reed Valve & Valve Plate to our valuable clients. These are available in different sizes & shapes. | ||||||||||

|

Reed Valve is a Flapper valve steel component used in different types of compressors for effective control of gas, fuel and air. Flapper Reed valves must be capable of working continuously for long periods without failure. A careful & controlled manufacturing process is essential for the proper function & longer service life of a Flapper Reed Valve. Flapper valves are used In :

|

|||||||||

Material : Chemical composition Sandvik Sweden of 7C27M02

High quality Martensentic chromium, stainless steel, alloyed with molybdenum give better corrosion resistant and higher fatigue strength resulting in a more efficient compressor because of lower flow losses across the valve.

FLATNESS - Extra accurate |

|

|

Features of IIS Flapper Valve Reed * High Fatigue Strength * High Purity * Good flatness & surface finish * Fine thickness tolerances * Radiused Edges * High Service temperature * Longer service life * Cost saving & Low maintenance |

|

|

Testing Facilities IIS has in house testing facilities for mecl1anical, Chemical, flatness, surface finish & edge radius. |

| Quality Assurance : International Industrial Springs has a quality Management System approved by internationally recognized organization. We hold Quality System certificate approval for ISO 9001:2000 |

|

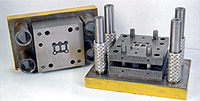

Manufacturing Facilities & Process : 1. Tool Design : |

|

2. Blanking : |

|||

|

|||

4. Stress Relieving : Reed valve are stress relieved in. order to reduce the residual stress from blanking operation wherever required Stress relieving is done on specially designed furnace with specified temperature. |

|||

|

|||

Valve Plate & Assembly

Valve Assemblies are used in Air Compressors for different types of applications. Valve Plates are made from High Chromium Stainless Steel material. Valve Plates are manufactured and heat treated in precision SPM's. Faltness, Parallism and Surface finish of Valve Plate is most important factor to increase efficiency of compressor valves. We have all testing facilities to Check Flatness, Parallism and surface finish of valve plates. We have developed a unique manufacturing process from our decades of experience and research. |

|

Address : Plot No. A-26, Road No. 10, Wagle Industrial Estate, Thane - 400604, Maharashtra, INDIA * Tel. : 2582 1941 / 2508 / 2581 3416 * Fax : 91-22-2582 4478 * Email :  Website : www.discspringsindia.com, www.internationalsprings.com, www.bellevillewashersindia.com , www.lockritewasher.com |